ICE BLUE Merino Wool Top

ICE BLUE Merino Wool Top

Sold in 100g = 3.5 ounce increments

64's - 21.5 micron, staple length 3". Approximate.

Merino is the softest in sheep wool fiber. Absolutely wonderful handspun into yarn, felted or used for blending your one of kind yarn or felt.

This fiber is prepared into a wool top. The fibers are combed in one direction. Perfect if handspinning worsted yarns, by spinning off the end, keeping your fibers parallel. Can be easily spun into a semi worsted (lofty woolen type) yarn over the fold or side of the preparation. Excellent fiber for blending colors or exotic fibers like angora, silk, kid mohair, cashmere, alpaca… If re-carded, drum or hand cards, will produce a roving for woolen spinning.

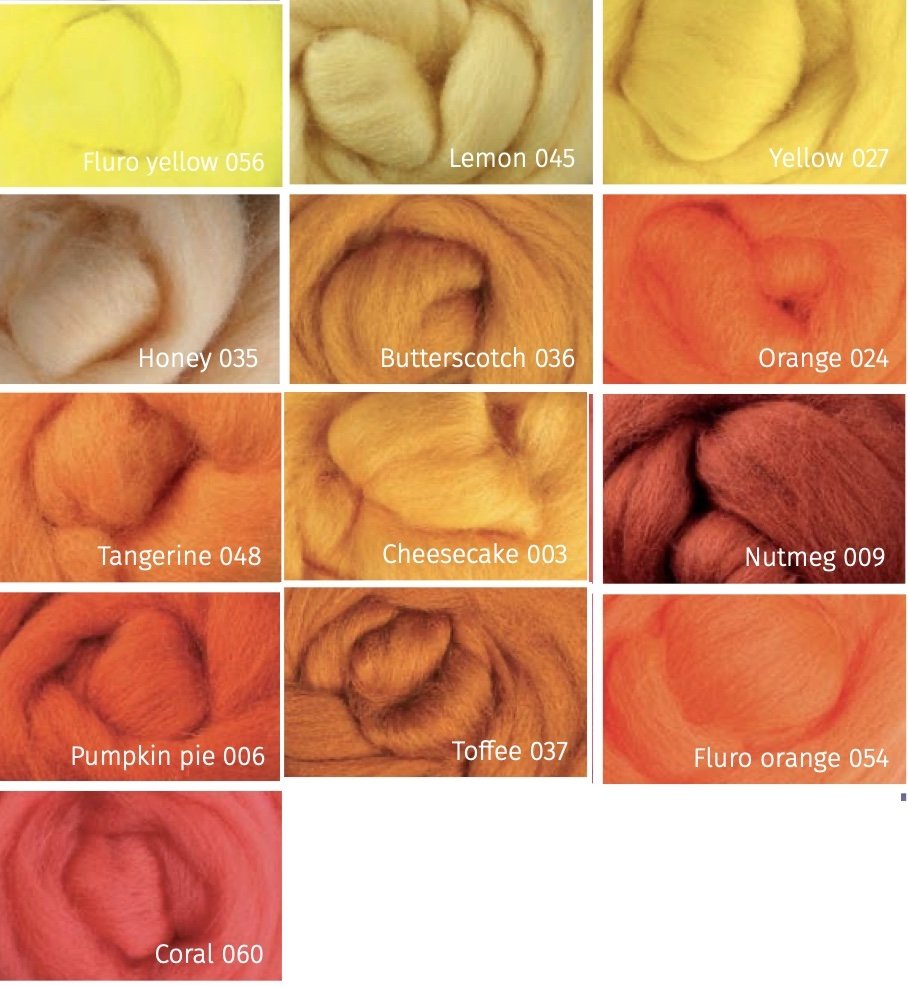

Images represent color - Monitors can vary to actual shade. Natural Color is the fiber shade of the Merino sheep, has not been dyed.

Click Here for PDF Ashford Shade Card

Ashford Handicrafts Fiber Grown and processed in New Zealand.

Save on Bulk Purchase Follow link below to special order from the full line in 500g bumps.

Ashford Merino sliver is a 100% New Zealand product with wool from pasture-fed sheep from our high country sheep stations. We know many of the farmers - some of whom have farmed the land for generations. They take great pride in the quality of their wool and the high standard of animal husbandry. The sheep are well cared for and are not mulesed.

After the sheep are shorn, on the farm, the wool is carefully skirted and checked. Only wool that is sound, clean with good fibre length, bulk and colour is selected. It is sent to a boutique New Zealand mill to be dyed, carded and combed.

It is scoured (washed) using an environmentally-friendly, biodegradable detergent . The wool is then dried and dyed. The dyes comply with the strict EU regulations and garments made from the sliver can be certified under the Oeko-Tex Standard 100. This standard is the most widely known standard for certification of ecologically-safe clothing. (Detailed information can be found at www.oekotex.com). The fiber is then gently opened and conditioned. Carding machines align the fibers and remove any foreign matter. It is then gilled and combed.